Philips has recently unveiled an innovative initiative called Fixables, aimed at enabling consumers to repair personal care products using 3D printing technology.

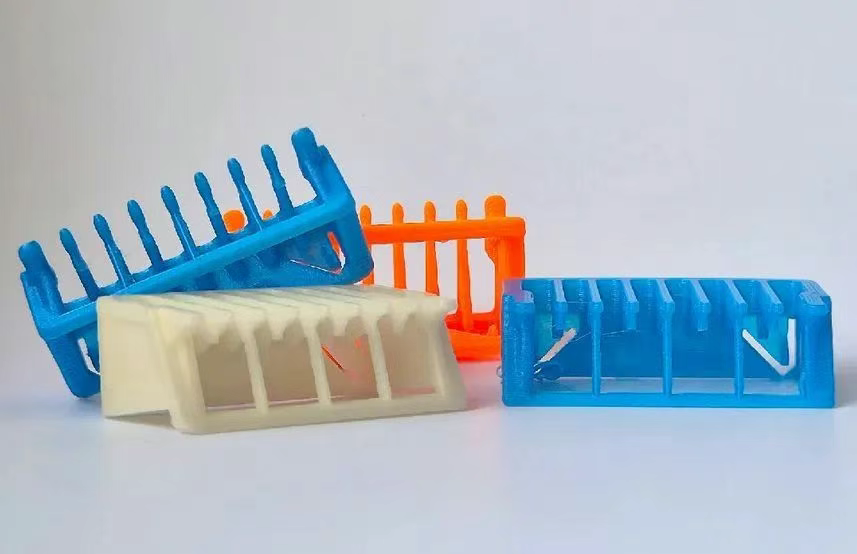

The project releases 3D-printable files for certain product replacement parts, allowing users to print them at home for a convenient and efficient repair experience. The goal is to extend product lifespans, reduce electronic waste, and promote sustainability.

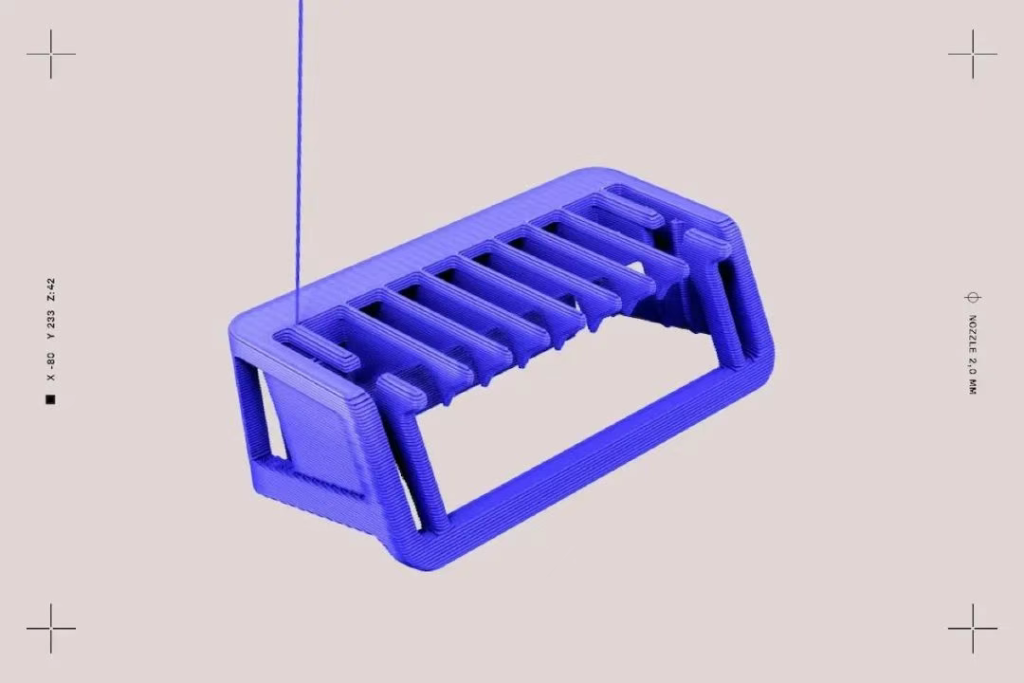

Currently in its early stages, the first downloadable part available is a 3mm comb guard for a shaver. Philips has pledged to gradually expand the range of supported products in the future.

Making Repairs Accessible for Everyday Wear and Tear

The Fixables platform focuses on addressing natural wear and tear in personal care products during regular use. Philips offers 3D-printed replacement parts that meet its high standards of quality and safety, helping users maintain performance and prolong the life of their devices.

This approach allows consumers to save on repair costs and reduce resource waste. The initiative is currently being piloted in the Czech Republic (home to Prusa Research), with plans to expand to more regions. All replacement part files will be available for free download on Printables.com.

Fostering a DIY Repair Culture and Moving Toward a Circular Economy

Philips noted that as many as 77% of European consumers prefer repairing old devices over replacing them. However, due to the lack of accessible repair options, most still end up buying new products. The Fixables project aims to address this gap.

By releasing 3D-printable spare part files with guaranteed quality, Philips hopes to make repair services more accessible and cater to more hands-on consumers. The project not only gives users more options for self-repair but also actively encourages a lifestyle that values maintenance and resource conservation.