PLA, or polylactic acid, is a thermoplastic made from renewable resources like corn and sugarcane. It’s biodegradable, environmentally friendly, and one of the most popular materials in desktop 3D printing. With easy printability, vibrant colors, and no unpleasant odors, PLA has earned its place as the go-to material for beginners and hobbyists alike—widely regarded as the “national material” of the 3D printing world.

From “Beginner-Friendly” to “Performance-Enhanced”: The Evolution of PLA

Despite its accessibility, traditional PLA is not without flaws—chief among them being brittleness and limited mechanical strength. To overcome these drawbacks, manufacturers have developed enhanced PLA variants. By adding toughening agents or blending PLA with polymers like TPU or ABS, they’ve created stronger, more impact-resistant versions known as “PLA+.”

In addition, composite PLAs that include fillers like carbon or glass fibers have emerged to boost rigidity and tensile strength.

However, once the brittleness issue was addressed, a new challenge surfaced: PLA’s low heat resistance.

Compared to common 3D printing materials, PLA’s heat deflection temperature (HDT) is relatively low—about 60 °C—while PETG is around 70 °C, ABS reaches 100 °C, and nylon can withstand up to 150 °C. Simply put, standard PLA can deform in boiling water, limiting its use in high-temperature applications.

HT-PLA: No Annealing Required, Heat Resistance Up to 150 °C

Just when the industry had accepted PLA’s 60 °C heat limit as a given, Polymaker broke through the ceiling. According to their project lead: “In 2014, we tackled PLA’s brittleness. Now, ten years later, we’ve redefined its heat resistance.”

Enter HT-PLA, the industry’s first high-temperature PLA that can withstand up to 150 °C—without the need for annealing. This makes it one of the rare “print-and-use” high-heat PLA options on the market today.

HT-PLA is compatible with standard PLA printing settings, requires no heated chamber, and supports printing speeds up to 300 mm/s. The initial launch includes 10 solid colors and 4 stunning gradient color options that balance functionality with visual appeal.

HT-PLA-GF: Engineered for Strength, Anneals in 30 Minutes

While HT-PLA solves the heat resistance issue, Polymaker recognized the need for even greater mechanical performance for engineering-grade applications. The result is HT-PLA-GF, a glass fiber-reinforced variant of HT-PLA that significantly boosts stiffness, tensile strength, and dimensional stability.

After a simple 30-minute annealing process, HT-PLA-GF can handle temperatures up to 110 °C—comparable to ABS—while offering nearly twice the rigidity and tensile strength. Polymaker plans to release nine standard colors for this line, including custom colors designed specifically for power tool components and other industrial uses.

Real-World Test: Survives the “Oven Challenge”

To validate the heat resistance claims, we ran a real-world test using a standard home oven (not a lab-grade setup). While results may vary depending on model geometry, print settings, and environmental factors, the test offers practical insight.

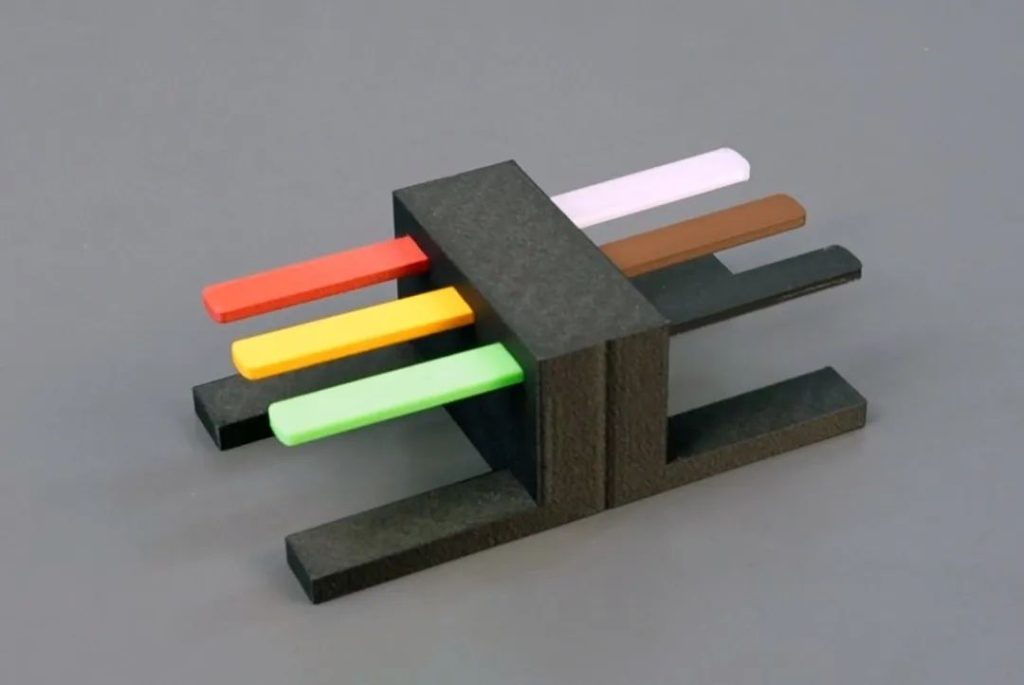

We printed a “tree” model with various branches made from six different materials:

- PLA (black)

- PETG (white)

- ABS (green)

- HT-PLA (brown)

- HT-PLA-GF (red, unannealed)

- HT-PLA-GF (yellow, annealed)

The trunk was printed using high-temperature PA612-CF15.

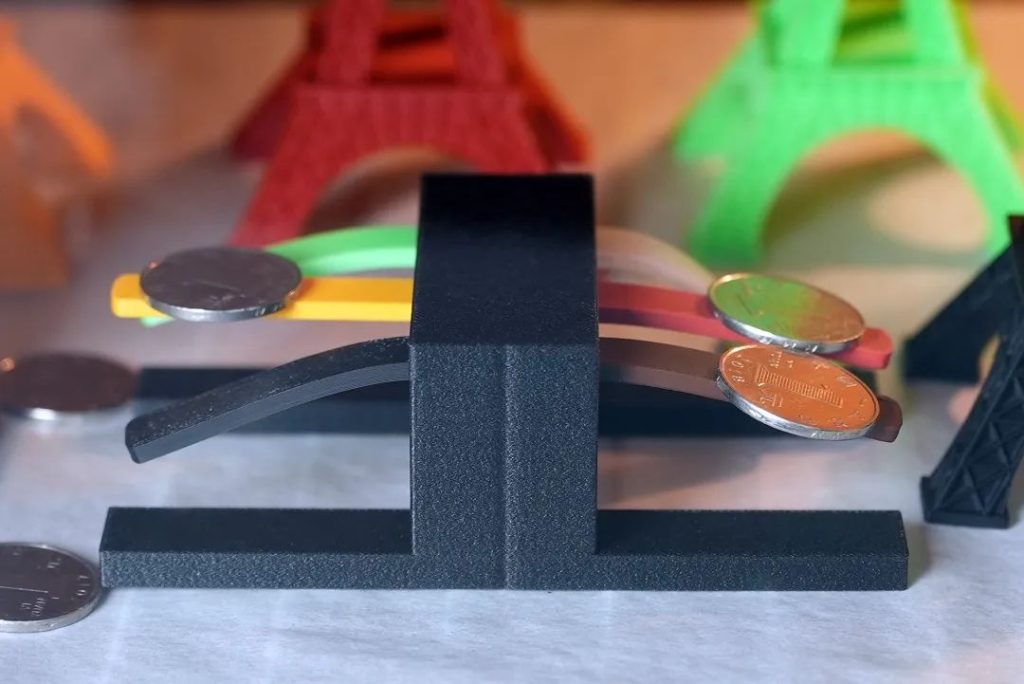

To detect deformation, coins were placed on each branch—if a coin fell, it indicated the material had softened significantly. The order of failure was:

- PLA (55 °C)

- PETG (70 °C)

- ABS (80 °C)

- HT-PLA (130 °C)

- HT-PLA-GF unannealed (140 °C)

- HT-PLA-GF annealed (150 °C)

We also printed Eiffel Tower models in all six materials and placed them under heat stress. The goal was simple: whichever tower remained standing the longest was the winner.

Final Thoughts: From Consumer-Grade to Engineering-Grade PLA

In summary, Polymaker’s HT-PLA series lives up to its promise of high heat resistance—especially the annealed HT-PLA-GF, which performs exceptionally well in both thermal stability and structural integrity.

If you’re printing parts that need to function reliably in hot environments, these high-temp PLA materials are worth exploring. And with Polymaker’s 6.18 promotional event currently underway, now might be a good time to give them a try.

PLA has long been associated with fragility and poor heat resistance. But with HT-PLA and HT-PLA-GF, Polymaker is rewriting the rules—signaling that PLA is no longer limited to consumer-grade projects, but is ready for engineering-grade performance.